Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

MIT researchers developed a 3D printer that produces complete, functional electric motors in one process, with parts costing about $0.50 each.

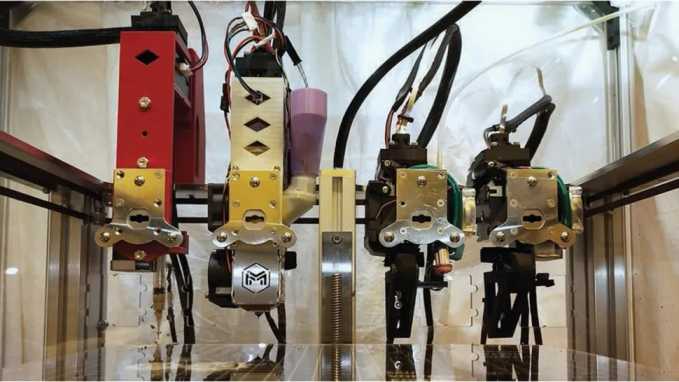

Researchers at the Massachusetts Institute of Technology have developed a 3D printing process that outputs fully functional electric motors in a single build, with only one post-print step required to magnetize the linear motor. The innovation could dramatically lower manufacturing costs and speed up production for complex electromechanical devices.

The new 3D printing technique developed by MIT integrates multiple materials and functional elements into a single print, eliminating the need for assembly. The process prints structural materials alongside conductors and motor windings, enabling the production of ready-to-use electric motors. After printing, researchers only needed to magnetize the motor’s components to make the device operational.

The system simultaneously deposits conductive and non-conductive materials in a coordinated build, allowing complex electromechanical architectures to be fabricated in one pass. This contrasts with traditional manufacturing, where motor parts are produced separately and then assembled, increasing both time and labor costs.

By reducing parts and assembly requirements, the MIT method significantly lowers production costs. With material costs around $0.50 per motor, the technology could enable cheaper custom motors for applications in robotics, consumer electronics and industrial automation, potentially transforming how electromechanical devices are manufactured at scale.

source: tomshardware